How to Optimize Membrane Bioreactor Performance for Maximum Efficiency

How to Optimize Membrane Bioreactor Performance for Maximum Efficiency

Blog Article

Membrane Layer Bioreactors Discussed: Reliable Solutions for Clean Water

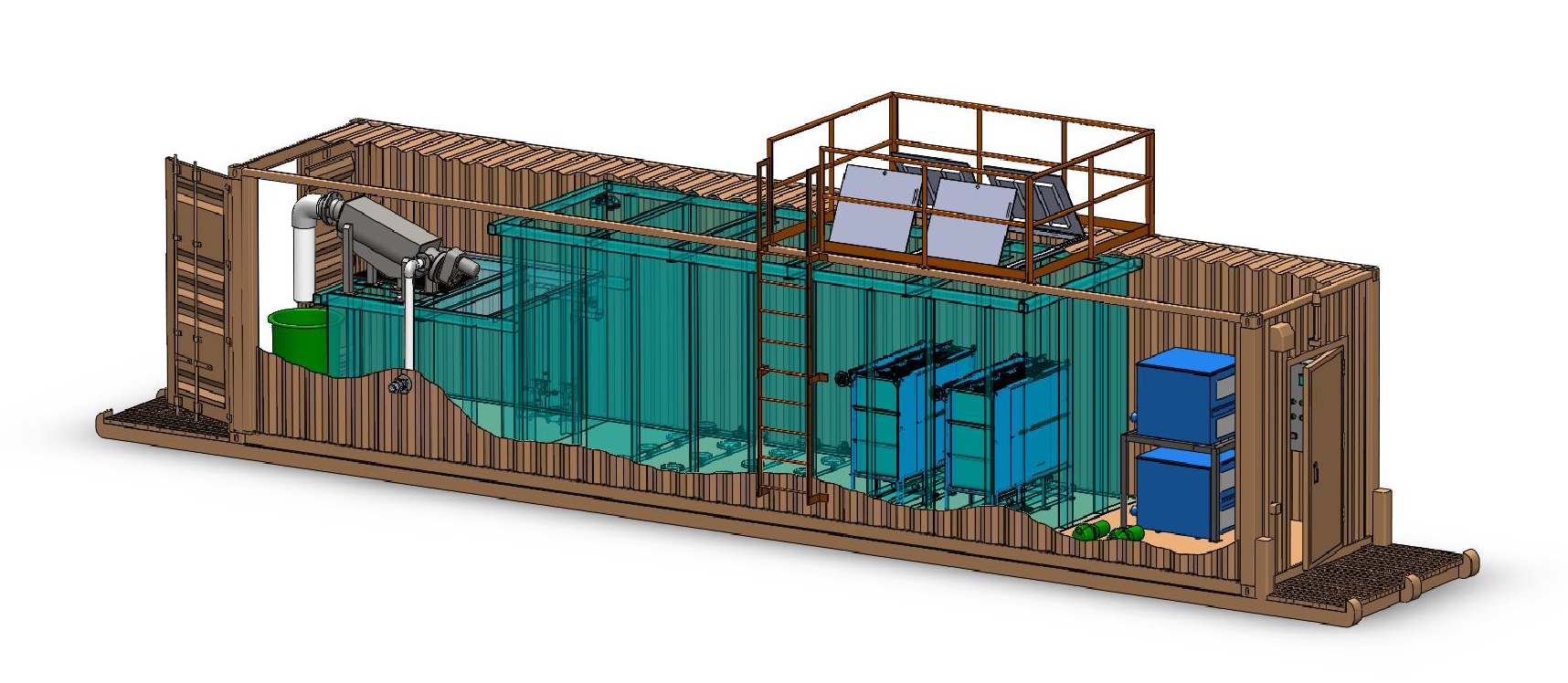

Membrane bioreactors (MBRs) have actually arised as an advanced remedy for addressing the pushing obstacles of wastewater treatment - Membrane Bioreactor. By integrating organic processes with advanced membrane purification, MBRs not just improve the quality of treated water yet likewise decrease the spatial requirements of therapy facilities.

What Are Membrane Layer Bioreactors?

Membrane bioreactors (MBRs) are advanced wastewater therapy systems that incorporate biological degradation procedures with membrane layer filtering innovation. This assimilation allows for the effective elimination of pollutants from water, making MBRs a preferred choice in various applications, consisting of community wastewater therapy and commercial effluent administration.

Among the vital advantages of MBRs is their ability to create top quality effluent, often ideal for reuse in watering or industrial procedures. Additionally, MBRs need a smaller impact compared to traditional treatment systems, making them suitable for metropolitan setups where space may be restricted.

Additionally, MBRs can effectively deal with varying influent lots and are less vulnerable to the results of hazardous shocks. These characteristics add to their expanding appeal as a sustainable option for addressing the enhancing need for tidy water while lessening environmental effects.

Just How Membrane Layer Bioreactors Work

While the operation of membrane layer bioreactors (MBRs) might appear complicated, it basically focuses on the synergy between organic procedures and membrane filtration. MBRs incorporate an organic treatment procedure, normally activated sludge, with a membrane separation system to deal with wastewater efficiently.

In an MBR system, wastewater is first introduced into a bioreactor where microorganisms weaken raw material and other contaminants. The biological task minimizes the focus of toxins while advertising the development of biomass. Following this organic therapy, the combined alcohol undergoes membrane layer purification, which can be microfiltration or ultrafiltration, relying on the preferred effluent top quality.

The membrane layers work as a physical obstacle, permitting water and tiny solutes to pass while retaining put on hold solids and bigger molecules. This makes it possible for the system to keep a high focus of biomass within the activator, improving the treatment efficiency.

Furthermore, the continuous splitting up of cured water from the biomass promotes a portable style and reduces the impact of the therapy center. Overall, the combination of biological degradation and membrane purification in MBRs results in effective and reputable wastewater treatment, ensuring top notch effluent appropriate for numerous applications.

Advantages of MBR Modern Technology

Among the vital benefits of membrane bioreactor (MBR) modern technology is its capability to produce high-grade effluent with a substantially decreased impact contrasted to traditional wastewater therapy methods. MBR systems properly integrate biological therapy and membrane purification, leading to exceptional elimination of pollutants, consisting of suspended solids, virus, and natural matter. This capacity results in effluent that often fulfills or exceeds rigorous regulatory requirements for reuse and discharge.

Additionally, MBR modern technology permits greater biomass focus, which improves the therapy efficiency and minimizes the required reactor quantity. This compact style is specifically advantageous in city areas where area is restricted. The functional flexibility of MBR systems likewise suggests they can adapt to varying influent top qualities and flow rates, making them appropriate for a wide variety of applications.

Furthermore, the reduced sludge manufacturing connected with MBR procedures adds to decrease operational and maintenance expenses. The membrane layers act as a physical barrier, reducing the threat of clogging and enabling longer operational durations between cleaning. Generally, the benefits of MBR modern technology make it an attractive solution for lasting wastewater therapy, resolving both ecological concerns and the requirement for reliable source monitoring.

Applications of Membrane Layer Bioreactors

With their flexibility and effectiveness, membrane bioreactors (MBRs) find applications across different markets, consisting of local wastewater treatment, commercial procedures, and also water improvement. In local setups, MBRs give a small remedy for dealing with wastewater, effectively removing pollutants while all at once producing high-quality effluent that meets rigorous regulatory standards. This makes them particularly ideal for locations with limited space.

In industrial applications, MBR modern technology is used for treating process water, specifically in sectors such as food and beverage, pharmaceuticals, and petrochemicals. These industries profit from MBRs' capability to handle high organic loads and their performance in recuperating valuable sources from wastewater, such as nutrients and water.

Moreover, MBRs play a critical function in water reclamation campaigns, making it possible for the reuse of treated wastewater for watering, industrial procedures, or perhaps as safe and clean water after additional therapy (Membrane Bioreactor). Their effectiveness in removing pollutants and virus makes them a trustworthy option for ensuring water high quality in numerous reuse applications

Future of Water Treatment Solutions

The future of water treatment remedies is poised for transformative innovations driven by technological technology and boosting environmental understanding. As international water scarcity comes to be a pressing problem, brand-new approaches, including membrane bioreactor (MBR) systems, are established to play a pivotal function in boosting the effectiveness and sustainability of water therapy procedures.

Emerging innovations such as synthetic knowledge and artificial intelligence are expected to enhance therapy procedures, enabling real-time surveillance and anticipating upkeep. This will enhance the general integrity and effectiveness of water treatment facilities. Improvements in membrane products, such as graphene and nanofiltration, assure to raise permeation prices and lower fouling, leading to lower energy usage and operational costs.

Additionally, the integration of renewable resource resources right into water therapy plants will certainly add to greener techniques. The circular economic situation version will certainly additionally go to my site obtain traction, encouraging the recuperation of beneficial sources from wastewater, such as nutrients and power.

Final Thought

Membrane bioreactors (MBRs) have emerged as an advanced solution for resolving the pressing challenges of wastewater therapy. By incorporating organic processes with innovative membrane purification, MBRs not only improve the top quality of click here for more treated water yet also reduce the spatial demands of treatment centers.One of the vital advantages of membrane layer bioreactor (MBR) technology is its capacity to produce high-grade effluent with a substantially lowered footprint contrasted to conventional wastewater treatment techniques.With their adaptability and efficiency, membrane layer recommended you read bioreactors (MBRs) locate applications across various sectors, consisting of municipal wastewater treatment, industrial procedures, and even water recovery.In conclusion, membrane bioreactors represent a considerable improvement in wastewater therapy technology, integrating biological processes with reliable membrane layer filtration to produce top notch effluent.

Report this page